- Engineering stress vs true stress pdf pdf#

- Engineering stress vs true stress pdf full#

- Engineering stress vs true stress pdf series#

If your bike has toeclips and straps or clipless (“step-in”) pedals, make sure you know how they work (see Section 4.

Engineering stress vs true stress pdf pdf#

Batavus HS50 Owners Manual FREE PDF DOWNLOAD. A go-to source of information about bicycle maintenance, repair and customization Diagrams 4 D iagrams IS 2000 PM 6 N

Engineering stress vs true stress pdf series#

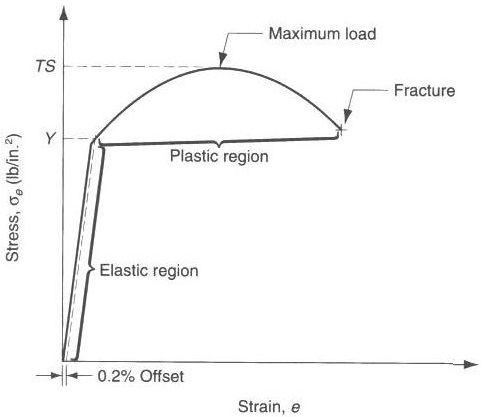

2009-Up ATV Models Viper 70 Silver Series (RXL-7009) | Viper 90 Silver Series (RXL-9009) | Viper 90R Silver Series (RXL-90R09) | 2009 Viper 150R (RXL-150R09) | YUKON II (CXL. You can always bypass this check by using LCSS instead of cards 3 and 4.Bicycle parts diagram pdf 2020 GT Tech Book. If cards 3 and 4 are used to define the curve, the job will stop due to an improper though conservative check of E against Ep. For example, if Ep = 3253 and E were set to an extremely low value, say 10, Etan is then equal to Ep*E/(Ep + E) = 9.97. In *MAT_24, this is exactly the input check that is made if LCSS=0 and cards 3 and 4 are blank (E must be greater than ETAN or else you get a fatal error).Īctually, this condition of E > Etan is ALWAYS met if a stress vs. epspl curve (presumably this is the steepest portion of the curve). effective plastic strain curve (in *MAT_PIECEWISE_LINEAR_PLASTICITY),Įtan = (Eh * E)/(Eh + E) where Eh = (true stress - SIGY)/(true strain - true stress/E)Į should not be less than Etan where Etan is computed from E and Ep, where Ep is the initial slope of the piecewise linear stress vs. In the case where the user elects to input only an initial yield stress SIGY and the tangent modulus Etan in lieu of a true stress vs. In any case, the first plastic strain value should be input as zero and the first stress value should be the initial yield stress. For plastics/polymers, you probably should consider the increase in recoverable strain as stresses increase (since the elastic component of strain may be quite large). For metals, E is very large compared to the yield stress so it's fairly common practice in the case of metals to just subtract off a constant value equal to the strain at initial yield from all subsequent strain values. Note that as the stress value increases, the recoverable strain ( true stress/E) increases as well. Įffective plastic strain (input value) = total true strain - true stress/E Using experimental data from a true stress vs. True stress is input directly for the stress values. effective plastic strain curve in a LS-DYNA plasticity model should be the residual true strains after unloading elastically. The effective plastic strain values input in defining a stress vs.

Engineering stress vs true stress pdf full#

Full iterative plasticity can be invoked for shells, at greater expense, for material models 3, 18, 19, and 24 by setting MITER=2 in *CONTROL_SHELL. Input of noisy experimental data may cause spurious behavior, particularly in the case of the default, 3-iteration plane stress plasticity algorithm for shells. When using *MAT_24, one should input a smoothed stress-strain curve utilizing a minimal number of points. True stress = (engineering stress) * exp(true strain) = (engineering stress) * (1 + engineering strain) where exp(true strain) is 2.71 raised to the power of (true strain).īe aware that experimental data always includes some degree of error and thus tends to be somewhat noisy or erratic. True strain = ln(1 + engineering strain) where ln designates the natural log true strain, not engineering stress or strain. First of all, you may check that your experimental data from a uniaxial tension test is expressed in terms of true stress vs.

0 kommentar(er)

0 kommentar(er)